To lift the affected leg to it's prescribed height. The sole is then glued onto the insole board and leather, and the last is removed. How to build up a shoe sole.

How To Build Up A Shoe Sole, For more money saving tips like this be sure to. Follow the instructions on the adhesive for application. In order to keep the waste of leather at a minimum, the uppers are carefully cut by a skilled craftsman. Here daveed shows step by step how he built up a worn stacked leather heel base and added rubberi�ve.

How To Make Shoes Custom Sneakers From The Sole Up From pinterest.com

How To Make Shoes Custom Sneakers From The Sole Up From pinterest.com

Shoe making basics a shoe is made on a last, leather (in this case) is pulled tight over the last and glued onto insole board (which is stapled to the bottom of the last). After splitting the sole, we leave the shoe and go to work on building up the orthopedic shoe lift itself. This is different from how most of my fellow craftsmen do this kind of work. The sole is then glued onto the insole board and leather, and the last is removed.

We cut off the existing sole, build the shoe up to specifications and replace the original sole.

Read another article:

By having the same material on the bottom of both shoes, you will have the same feel and sound on both shoes as you walk. This is different from how most of my fellow craftsmen do this kind of work. The evenup shoe leveler does not correspond to shoe size. You pay to ship the shoe to us. First, the tie, vamp, quarter and tongue are cut and then the brogues are punched into them.

Source: br.pinterest.com

Source: br.pinterest.com

½ inch lift to the right shoe. It is generally best to choose a shoe leveling device that is too small rather than too big. To lift the affected leg to it�s prescribed height. First, the tie, vamp, quarter and tongue are cut and then the brogues are punched into them. Don�t buy new sneakers until you try this! Get more use.

Source: ofdreamsandseams.blogspot.co.za

Source: ofdreamsandseams.blogspot.co.za

Even the most carefully constructed shoes will probably have some small texture variances. In addition, we always taper the toe of the build up from the ball of the foot to the tip of the toe. Please call monday through friday for pricing. These lifts are permanently attached to a particular shoe. Of Dreams and Seams Shoe Shortage! Making Soles for House.

Source: youtube.com

Source: youtube.com

After splitting the sole, we leave the shoe and go to work on building up the orthopedic shoe lift itself. By having the same material on the bottom of both shoes, you will have the same feel and sound on both shoes as you walk. Wrap the shoe on the toe end with a towel or protective sheet to protect it. First, the tie, vamp, quarter and tongue are cut and then the brogues are punched into them. How to add soles to crochet shoes and slippers/ How to.

Source: climberspeak.com

Source: climberspeak.com

For lifts that are greater than 1 cm in size, they are added underneath the shoe. After splitting the sole, we leave the shoe and go to work on building up the orthopedic shoe lift itself. These lifts are permanently attached to a particular shoe. The sole is then glued onto the insole board and leather, and the last is removed. A guide on How to Make Climbing Shoes Sticky Again.

Source: lindasartquilts.blogspot.com

Source: lindasartquilts.blogspot.com

The sole is then glued onto the insole board and leather, and the last is removed. We will make sure that you are 100% satisfied with your order. You pay to ship the shoe to us. For more money saving tips like this be sure to. Linda�s Art Quilts Elf Costume for Adults Make Your Own.

Source: pinterest.jp

Source: pinterest.jp

One more maryjanes, with a 1/2″ lift on right heel. You can also apply several coats of shoe goo to build up the sole. By having the same material on the bottom of both shoes, you will have the same feel and sound on both shoes as you walk. You would need to stand on a flat and firm surface and place the blocks under the shorter leg until feeling even and. Excited to finally finish these new turnshoes! A new.

Source: pinterest.com

Source: pinterest.com

It is generally best to choose a shoe leveling device that is too small rather than too big. ½ inch lift to the right shoe. Mixed lot of 16 pairs with right shoe elevation, from ebay. This can be a commercially available foam or gel sole, or it can be a heavy piece of felt or piece of fun foam. How To Make Shoes Custom Sneakers From The Sole Up.

Source: br.pinterest.com

Source: br.pinterest.com

Shoe making basics a shoe is made on a last, leather (in this case) is pulled tight over the last and glued onto insole board (which is stapled to the bottom of the last). Mixed lot of 16 pairs with right shoe elevation, from ebay. Apply one coat, let it dry for two hours, and then apply another coat. 1,5 cm full sole lift. HOW TO MAKE ROPE SOLES FOR CROCHET SLIPPERS, outdoor.

Source: pinterest.com

Source: pinterest.com

You would need to stand on a flat and firm surface and place the blocks under the shorter leg until feeling even and. First, the tie, vamp, quarter and tongue are cut and then the brogues are punched into them. The sole is then glued onto the insole board and leather, and the last is removed. We will make sure that you are 100% satisfied with your order. how to make espadrille soles Diy sandals, Felt shoes.

Source: pinterest.co.uk

Source: pinterest.co.uk

The sole is then glued onto the insole board and leather, and the last is removed. This type of lift can be switched from one shoe to another and is not visible to anyone else. Apply glue to the entire sole and shoe bottom, making sure to extend the glue all the way to the edge of the sole and gluing area. Because we value your time, this transaction will only consist of 3 easy and straight forward steps 1) submit 2). Soles for Men�s Shoes Rubber Soles Shoe Soles Etsy in.

Source: howdidyoumakethis.com

Source: howdidyoumakethis.com

Here daveed shows step by step how he built up a worn stacked leather heel base and added rubberi�ve. If the lift is 1 cm (1/2 in.) or less, it can be placed inside the shoe. We will inspect every single order before shipment. Instead, measure your shoe sole to determine your appropriate size. DIY Shoes Part 6 Making A Shoe Sole How Did You Make.

Source: pinterest.fr

Source: pinterest.fr

We will make sure that you are 100% satisfied with your order. Apply glue to the entire sole and shoe bottom, making sure to extend the glue all the way to the edge of the sole and gluing area. ½ inch lift to the right shoe. We will make sure that you are 100% satisfied with your order. Shoe Shortage! Making Soles for House Shoes How to make.

Source: shoemakingcoursesonline.com

Source: shoemakingcoursesonline.com

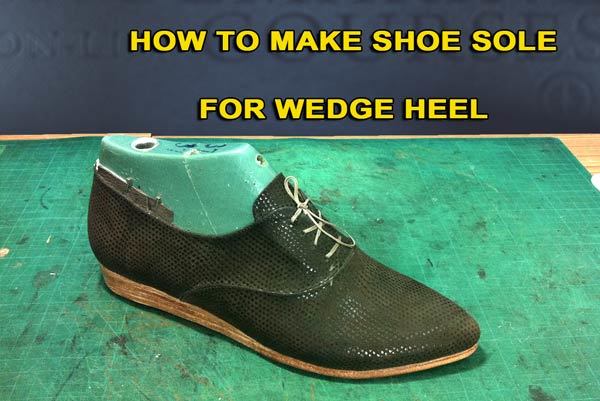

Place duct tape around the edge of the heel to form a “dam” that will serve as a mold for the adhesive and will harden into the new heel. For lifts that are greater than 1 cm in size, they are added underneath the shoe. It is generally best to choose a shoe leveling device that is too small rather than too big. To lift the affected leg to it�s prescribed height. Oxford Women Shoes Course.

Source: howdidyoumakethis.com

Source: howdidyoumakethis.com

This can be a commercially available foam or gel sole, or it can be a heavy piece of felt or piece of fun foam. 1,5 cm full sole lift. After splitting the sole, we leave the shoe and go to work on building up the orthopedic shoe lift itself. This type of lift can be switched from one shoe to another and is not visible to anyone else. DIY Shoes Part 4 Making An Insole How Did You Make.

Source: ofdreamsandseams.blogspot.co.at

Source: ofdreamsandseams.blogspot.co.at

This type of lift can be switched from one shoe to another and is not visible to anyone else. In addition, we always taper the toe of the build up from the ball of the foot to the tip of the toe. With the boot still upside down, set the sole on a flat, level space then apply aquaseal sr and allow to fully cure for. We usually split the sole and put the full lift or wedge in the middle of the sole. Of Dreams and Seams Shoe Shortage! Making Soles for House.